A Guide to Selecting the Best LVL Formwork Timber for Your Needs

In the construction industry, choosing the right materials is crucial to ensure the success and longevity of any project. One such material that is widely used in formwork construction is Laminated Veneer Lumber (LVL) formwork timber. LVL formwork timber offers numerous advantages over traditional timber, making it a popular choice among contractors and builders.

Understanding LVL Formwork Timber

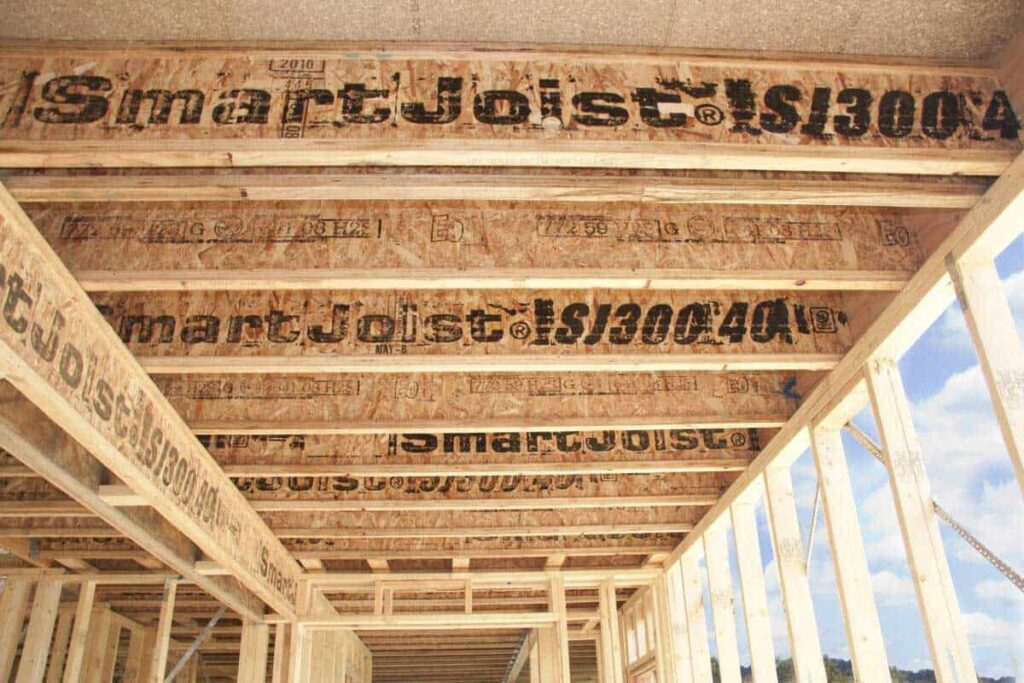

Before delving into the factors to consider when selecting LVL formwork timber, it’s important to understand what exactly it is. LVL formwork timber is a type of engineered timber product that is specifically designed for use in formwork applications. It is made by bonding multiple layers of thin wood veneers together with adhesive, resulting in a strong and stable material that is resistant to warping and splitting.

What is LVL Formwork Timber?

LVL formwork timber is essentially a composite material that combines the natural beauty and advantages of wood with the strength and durability of engineered materials. It is commonly used for concrete formwork, providing a robust and reliable support system for various construction projects.

Benefits of Using LVL Formwork Timber

There are several benefits to using LVL formwork timber. Firstly, it offers superior strength and load-bearing capacity compared to traditional timber. This means that it can withstand the heavy loads exerted by concrete during the curing process, reducing the risk of formwork failure. Additionally, LVL formwork timber is highly resistant to moisture, making it suitable for use in humid or wet environments.

But that’s not all! LVL formwork timber also boasts exceptional fire resistance. Its composition and manufacturing process make it less susceptible to ignition and combustion, providing an added layer of safety on construction sites. This is particularly important in high-rise buildings or structures where fire safety is a top priority.

Furthermore, LVL formwork timber is known for its excellent acoustic properties. Its dense structure helps to absorb and dampen sound vibrations, making it an ideal choice for projects that require noise reduction, such as theaters, concert halls, or recording studios. This not only enhances the overall comfort and experience for occupants but also contributes to the overall quality of the construction.

Another advantage of LVL formwork timber is its dimensional stability. Unlike solid timber, LVL formwork timber is less susceptible to shrinkage, expansion, and warping, ensuring consistent formwork performance throughout the entire construction process. This stability also translates to improved accuracy and precision in the final concrete structure, resulting in a higher quality finished product.

Furthermore, LVL formwork timber is eco-friendly, as it is made from sustainably sourced wood and can be recycled at the end of its life cycle. By choosing LVL formwork timber, construction professionals can contribute to a more sustainable and environmentally conscious industry, reducing the reliance on non-renewable materials and minimizing waste.

So, when it comes to selecting formwork timber, LVL is undoubtedly a top choice. Its strength, durability, resistance to moisture and fire, acoustic properties, dimensional stability, and eco-friendliness make it a versatile and reliable material for a wide range of construction projects. Whether you’re working on a residential building, a commercial complex, or an infrastructure project, LVL formwork timber is sure to meet and exceed your expectations.

Factors to Consider When Choosing LVL Formwork Timber

When selecting LVL formwork timber for your project, there are several key factors that you should consider to ensure optimal performance and cost-effectiveness.

Choosing the right LVL formwork timber is essential for the success of your construction project. By paying attention to key factors such as timber quality, size, dimensions, durability, and resistance to elements, you can ensure that your formwork performs efficiently and effectively throughout the construction process.

Timber Quality and Strength

The quality and strength of LVL formwork timber are crucial factors to consider. Look for timber that is manufactured using high-quality veneers and adhesive. The strength of the timber can be determined by its grade and span rating. Higher-grade timber with a higher span rating will typically offer greater load-bearing capacity, allowing you to use fewer supports and reducing construction time and costs.

Additionally, consider the manufacturing process of the timber to ensure that it meets industry standards for quality and performance. Timber that undergoes rigorous quality control measures during production is more likely to provide consistent strength and reliability for your formwork needs.

Size and Dimensions

The size and dimensions of the LVL formwork timber are also important considerations. Ensure that the timber dimensions are suitable for your specific formwork requirements. Consider factors such as the thickness, width, and length of the timber pieces. Opting for standardized sizes can simplify formwork assembly and reduce wastage and material costs. Read more about standardized on https://www.gettingsmart.com/2013/04/26/education-standardization-essential-or-harmful/

Moreover, take into account the weight of the timber pieces, especially if manual handling is involved in the construction process. Choosing timber sizes that are manageable and easy to transport can improve on-site efficiency and safety for your workers.

Durability and Resistance to Elements

Since LVL formwork timber is exposed to the harsh outdoor environment during construction, it is important to select timber that is treated or naturally resistant to decay and insect damage. Properly treated timber will have a longer lifespan and reduce the need for frequent replacements, saving you both time and money in the long run.

Consider the environmental conditions of your construction site and choose LVL formwork timber that is specifically designed to withstand factors such as moisture, temperature fluctuations, and UV exposure. By investing in durable and weather-resistant timber, you can ensure the longevity and performance of your formwork system under varying weather conditions.

Tips for Purchasing LVL Formwork Timber

After considering the various factors, finding a reliable and reputable timber supplier is crucial. Here are some tips to help you make an informed purchase decision:

Identifying Reliable Timber Suppliers

Do thorough research to identify timber suppliers that have a good reputation in the industry. Look for suppliers with a track record of supplying high-quality timber and delivering excellent customer service. Read customer reviews and seek recommendations from other contractors or builders.

When researching timber suppliers, it’s also beneficial to inquire about their sourcing practices. Suppliers who prioritize sustainable forestry practices contribute to the preservation of natural resources and help combat deforestation. Understanding where the timber comes from can give you insight into the supplier’s commitment to environmental responsibility.

Checking Timber Certification and Standards

Ensure that the timber supplier adheres to relevant certification and quality standards. Look for certifications such as the Forest Stewardship Council (FSC) certification, which ensures that the timber is sourced sustainably from responsibly managed forests.

In addition to certifications, consider the specific standards that the timber meets. For formwork applications, it’s essential to verify that the timber has the necessary strength and durability to withstand the pressures of construction. Look for timber that complies with industry standards for formwork materials to ensure safety and performance on your project. Click here to find more about pressures.

Comparing Prices and Value for Money

Obtain quotes from multiple timber suppliers and compare prices. However, keep in mind that price should not be the sole determining factor. Consider the overall value for money, taking into account factors such as timber quality, durability, and service provided by the supplier.

When evaluating the value for money, factor in the supplier’s after-sales support and any additional services they offer. A supplier that provides assistance with timber selection, technical guidance, or on-site support can add significant value to your purchase. While cost is important, investing in a reliable supplier who offers comprehensive support can lead to long-term benefits for your construction projects.

Proper Handling and Maintenance of LVL Formwork Timber

Once you have selected and purchased the LVL formwork timber, proper handling and maintenance are essential to ensure its longevity and performance.

When it comes to Laminated Veneer Lumber (LVL) formwork timber, understanding the nuances of its storage, handling, and maintenance can significantly impact its durability and effectiveness in construction projects. Beyond just the initial selection process, taking the necessary steps to care for this crucial material can make a substantial difference in its lifespan and overall quality.

Storage and Handling Guidelines

Store the timber in a dry and well-ventilated area to prevent moisture damage. Moisture is a primary adversary of timber, as it can lead to warping, mold growth, and structural instability. By keeping the LVL formwork timber in a controlled environment with adequate airflow, you can mitigate the risks associated with dampness and ensure the material remains structurally sound.

Furthermore, it is imperative to shield the timber from direct sunlight and extreme heat, as prolonged exposure can not only compromise the integrity of the material but also affect its dimensional stability. Implementing proper storage practices, such as covering the timber with a tarp or storing it in a shaded area, can safeguard it from environmental stressors and prolong its usability.

Maintenance Tips for Longevity

Regularly inspect the LVL formwork timber for signs of damage or decay. Conducting routine checks can help identify any issues early on, allowing for timely repairs or replacements to maintain the formwork’s structural integrity. Addressing any damages promptly is crucial in preventing safety hazards on the construction site and ensuring the efficiency of the formwork system.

In addition to visual inspections, incorporating a cleaning regimen into the maintenance routine can enhance the longevity of the timber. Removing dirt, debris, and concrete residue not only preserves the aesthetic appeal of the formwork but also prevents potential abrasions or chemical reactions that could compromise its performance. Applying suitable timber preservatives or coatings can further fortify the material against moisture intrusion, fungal growth, and other environmental factors, extending its service life and optimizing its functionality.

Environmental Impact of LVL Formwork Timber

As awareness of environmental sustainability grows, it is essential to consider the environmental impact of construction materials, including LVL formwork timber.

When it comes to the environmental impact of LVL formwork timber, it is crucial to delve deeper into the production process. The manufacturing of LVL (Laminated Veneer Lumber) involves bonding together layers of wood veneers with adhesives. While this process is energy-intensive, advancements in technology have led to the development of more sustainable adhesives with lower levels of volatile organic compounds (VOCs). These eco-friendly adhesives reduce the environmental footprint of LVL production, making it a more environmentally friendly choice compared to traditional solid timber formwork.

Sustainability of LVL Formwork Timber

LVL formwork timber is considered a sustainable choice due to its use of renewable resources. It is typically manufactured from fast-growing softwood species, reducing the reliance on slow-growing hardwoods. Additionally, LVL formwork timber can be recycled at the end of its life cycle, further minimizing environmental impact.

Furthermore, the sustainable forestry practices employed in sourcing the raw materials for LVL formwork timber play a significant role in its environmental credentials. Forest certification programs, such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC), ensure that the timber comes from responsibly managed forests. These certifications guarantee that for every tree harvested, more trees are planted, maintaining the forest’s health and biodiversity.

Disposal and Recycling Options

When the formwork is no longer needed, it is important to dispose of or recycle the timber responsibly. Explore recycling options in your area or consider donating the timber to organizations or individuals who can repurpose it. By opting for responsible disposal or recycling, you can contribute to reducing waste and minimizing the environmental footprint of your construction project.

By considering the factors outlined above and following proper handling and maintenance procedures, you can select the best LVL formwork timber for your needs. Make an informed choice, and enjoy the numerous benefits that LVL formwork timber offers in terms of strength, durability, and environmental sustainability.

Other resources: The Advantages of LVL Timber in Heavy-Duty Construction Formwork